Designed by Dutch architectural firm UNStudio and constructed by Ardmore Ltd, the Canaletto residential tower is situated on City Road in the Islington district of London.

A significant landmark like Canaletto, nominated for the Award of Excellence of Best Tall Building Europe, deserves to be at its best at all times. Therefore the developer of the project, Groveworld, contacted and contracted XSPlatforms for the design, installation and handling of an innovative rooftop Building Maintenance Unit (BMU).

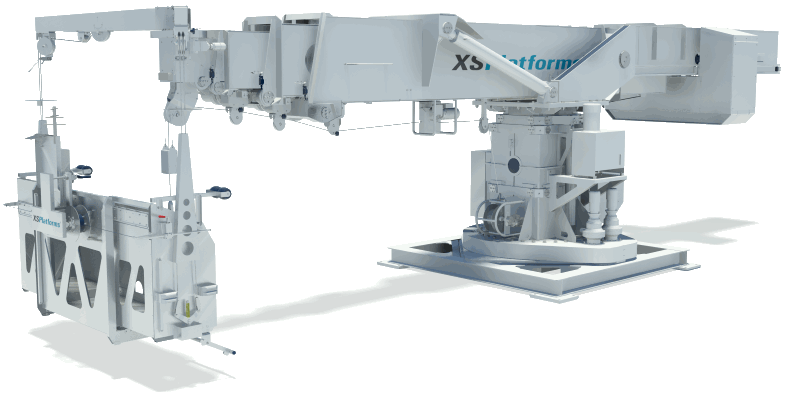

BMU with maximum reach

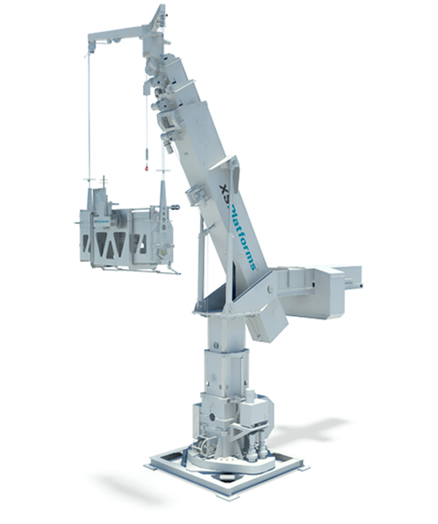

Our engineering department took this challenge and they delivered. Designing a custom BMU solution consisting of a fixed, telescopic roof car that is installed near the center of the roof. The column of the roof car can extend in a vertical way, and the jib of the machine extends horizontally, ensuring that all of the facade can be reached. When all of the parts are retracted invisible parking is possible.

When activated for use, the vertical column of the BMU starts to top out with a vertical stroke of approx. 2.3 meters (7.5 feet) before the telescopic jib section is lowered to a horizontal position. Once vertically deployed and ready to extract, the telescopic jibs can be extended to a maximum outreach of up to 22 meters (72 feet). Combined with its 360 degree slewing function it is possible to reach all facade elements in each direction from a single center point on the roof.

Adjustable cradle

When the BMU for Canaletto was installed, construction of the building was still in full swing. For this reason we delivered an extra gondola with the unit so that the roof car could assist in lifting materials during construction.

When construction was completed and the roof cars main focus was to assist in maintaining the tower, the “construction gondola” was switched with the specially designed cradle for the BMU.

A perfect fit

Because of the curved shapes of the facade the gondola that is used needs to be a perfect fit. The challenge for our engineering department was to create a cradle that could fit with each different areas. Therefore, this gondola is designed to be manually adjusted in width before being lowered along the facade. This way the operator of the BMU can choose the best configuration of the cradle before heading down to work.

Combined with a strong Glass Replacement Unit (GRU), with a maximum load of 750 kg (1653 lbs), this BMU design is the perfect fit for Canaletto.